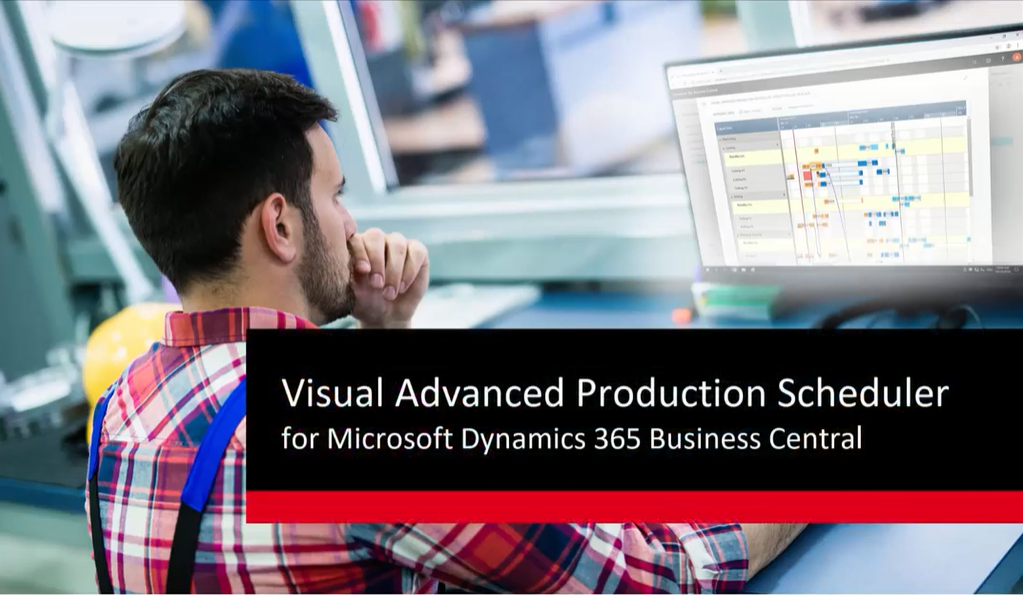

Planning of production capacity using the drag & drop method

Using the “drag on drop” method, you can quickly and conveniently change the production schedule, which helps in taking efficient corrective actions.

VAPS is an add-on to Business Central, in which the production planning procedure is based on a graphical tool based on Gantt charts, used to modify the production schedule and allow “live” control of the changing workstations. The production planning process takes place through the standard Business Central algorithms – the planning sheet, while the improvement of production thanks to Netronic VAPS is a graphical reflection of the generated plan and allows you to change the planned schedule by drag-and-drop operations, which we want to change the schedule, and then allows save changes and return information about changes to Business Central.

Using the “drag on drop” method, you can quickly and conveniently change the production schedule, which helps in taking efficient corrective actions.

The production planning process

takes place in Business Central

VAPS is graphical

reflection of the generated plan.

Ability to quickly view workload and planned time frames. As a result, VAPS helps to maximize throughput and reduce resource downtime resulting from the so-called bottleneck.

The video on the left shows the production planning solution Visual Advanced Production Scheduler, which is dedicated for Microsoft Dynamics 365 Business Central. The presentations are conducted by the CEO and Co-Owner of NETRONIC, the producer of the VAPS solution.